MEDIA

Article type

- Article

- Brochure

- Case study

- E-book

- Event

- News

- Whitepaper

MEDIA TYPE

- Audio

- Image

- Video

PRODUCT

- AM-Feed

- AM-Vision

- AM-Sort

- AM-Quality

- AM-Bagging

It started in mid-February with 27 little avatars behind a screen of COVID 19 restrictions listening to our proposal for a half-year internship. The assignments consisted of developing a ‘horizontal packaging solution’ for the automatic packaging of products in plastic bags and a ‘production order recombination unit’ where various parts, produced in different departments from…

Ziggzagg, the Belgian 3D printing service provider and pioneer in adopting HP Multi Jet Fusion technology, invests in AM-Flow’s broad range of additive manufacturing workflow automation solutions as the basis of its digital factory in Aalter, starting with the AM-VISION and the AM-SORT. In addition, both parties agreed to partner in the further development of…

“Just like other 3D-printservice providers, several post processing steps are done manually at Oceanz. The increase in costs and lead times due to these manual steps has made us realize the necessity to develop and apply new technologies, such as automatic identification, Artificial Intelligence (AI) and machine learning. We have opened up our production facility…

Sculpteo, the leading online 3D printing service provider in France, has recently signed a contract at our development centre in Amsterdam to purchase the AM-Flow system. This cutting-edge system will revolutionize Sculpteo’s production process by using advanced vision technology to identify parts, automate sorting and label & bagging capabilities. Marion Timmermans, Sales Director of the…

These are the first conclusions of a test BMW is conducting with AM-Flow’s AI-based recognition system. They were recently presented at Rapid.Tech 3D. Philipp Obst of BMW Group, which has a large AM center in Munich, shared many details during the online conference about the car manufacturer’s first experiences with the Dutch system. Automatic recognition…

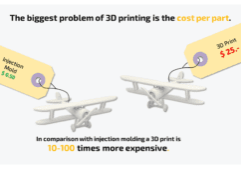

So, what is holding additive manufacturing back from broad industrial adoption and scalability? As with most things in the industry, a lot of it comes down to cost. Today, the cost of 3D printing parts is still too high to be truly viable for many applications. To give an idea, the price of 3D printing…

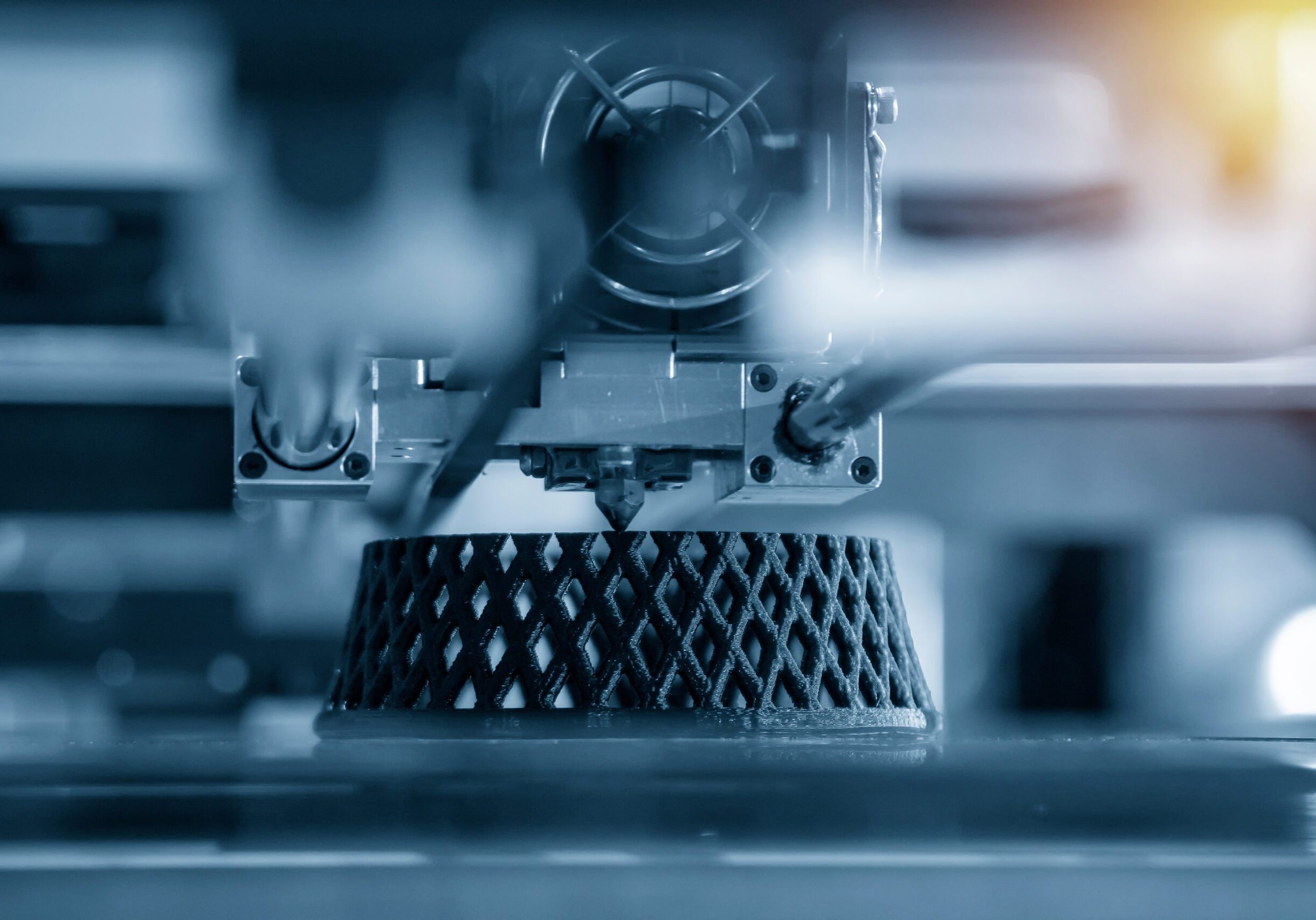

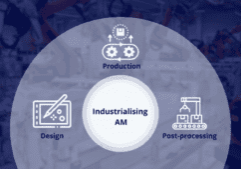

As manufacturing continues to evolve, so too must production processes. One area that has seen significant growth in recent years is Additive Manufacturing, also known as 3D printing. This technology allows for the creation of complex parts and components with a high degree of precision and customization. However, as with any manufacturing process, scaling up…

Automation solutions, from robots to software, can minimise touch labour, save costs, and improve consistency and quality. But where are we today in terms of automation in additive manufacturing? The article highlights four key trends driving the development of automation solutions in AM. 3. Automating post-production processes It’s estimated that 46% of businesses’ AM costs…

Automating design for additive manufacturing A significant part of designing for additive manufacturing (DfAM) remains manual. Even a skilled engineer can spend from 30 minutes to a few hours on a new part understanding the best orientation, technology and material. For manufacturers looking to adopt AM for hundreds of parts, it could cost tens of…

AM-Flow is one of 6 winners – alongside Nexa3D, 3DSystems, Intellegens, and Sigma Labs – chosen across 6 categories from among the many companies presenting the latest technical solutions at the event. The selection of award winners was made by a combination of an expert panel and attendee votes at the event. The whole team…

- « Previous

- 1

- 2

- 3

- 4

- Next »