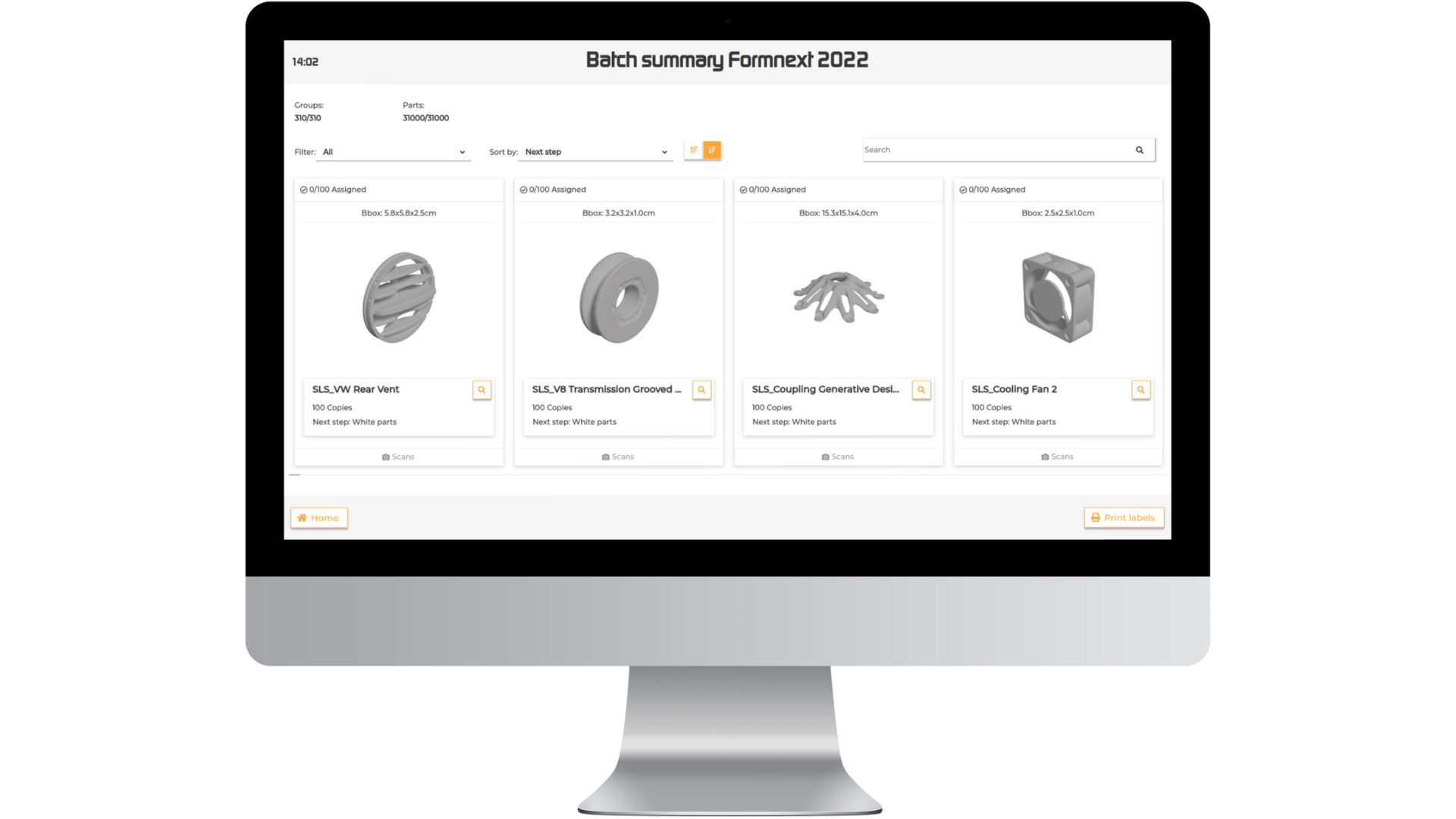

AM-Vision leverages advanced image recognition and AI algorithms to swiftly and accurately identify 3D-printed parts based on their geometry, size, and color. With the capability to process 5,760 parts in just 8 hours, AM-Vision sets a new standard in efficiency and precision for additive manufacturing.

- “The bottlenecks in the industry right now are largely in the post processing side, so everything after the printer. While we continue to grow, we can not just add human labor to continue to simply sort parts. That’s something we have been aggressively trying to resolve and explains our interest in AM-Flow. We are very impressed by the AM-Flow technology.”

Steve Grundahl | CEO Midwest Prototyping, US - 'As other 3D printing service providers, Oceanz’ part of the post processing workflow is also manually. That is why, for our growth, we see the importance of applying and developing new technological principles, such as automatic identification, Artificial Intelligence and machine learning,”

Erik van der Garde | CEO Oceanz, NL - “As companies scale their AM operations, they increasingly rely on automation. However, the potential to scale is limited by the post processing, which today is still mostly a manual process. Scaling this manual process by simple adding people increases costs, variability and doesn’t increase reliability. If you want to scale production, the only way forward is to automate post processing . . . but that easier said than done.”

Bart Van der Schueren | CTO Materialise, BE - “We want to strengthen our value for money proposition by lowering cost and optimizing lead time by business and manufacturing automation. We rather invest at an early stage; it is harder to change processes once we run 10 machines and increased the headcount. We aim to create a scalable infrastructure that enables fast but organized growth that does not compromise quality or customer experience”

Markus May | CEO 3Faktur, DE - “Integrating AM-Flow's identification and sorting capabilities has optimized our SLS and MJF processes, balancing density and geometry to reduce build costs. Streamlined administrative tasks and enhanced quality tracking have significantly cut non-value-added time and integrated critical quality data into our production system. Consequently, our production output increased by 70% in six months, and our non-conformance rate dropped from 1.6% to below 0.7%.”

Kason Knight | Managing Director i-SOLIDS, US - ProM

- “Integrating AM-Flow's identification and sorting capabilities has optimized our SLS and MJF processes, balancing density and geometry to reduce build costs. Streamlined administrative tasks and enhanced quality tracking have significantly cut non-value-added time and integrated critical quality data into our production system. Consequently, our production output increased by 70% in six months, and our non-conformance rate dropped from 1.6% to below 0.7%.”

Kason Knight | Managing Director i-SOLIDS, US - 3DStep

- “The bottlenecks in the industry right now are largely in the post processing side, so everything after the printer. While we continue to grow, we can not just add human labor to continue to simply sort parts. That’s something we have been aggressively trying to resolve and explains our interest in AM-Flow. We are very impressed by the AM-Flow technology.”

Steve Grundahl | CEO Midwest Prototyping, US - Sculpteo

- “We want to strengthen our value for money proposition by lowering cost and optimizing lead time by business and manufacturing automation. We rather invest at an early stage; it is harder to change processes once we run 10 machines and increased the headcount. We aim to create a scalable infrastructure that enables fast but organized growth that does not compromise quality or customer experience”

Markus May | CEO 3Faktur, DE - Creabis

- 'As other 3D printing service providers, Oceanz’ part of the post processing workflow is also manually. That is why, for our growth, we see the importance of applying and developing new technological principles, such as automatic identification, Artificial Intelligence and machine learning,”

Erik van der Garde | CEO Oceanz, NL - ZiggZagg

- Shapeways

- KLS Martin

- Weerg

SOFTWARE

AM-Logic integrates all AM-Flow modules with your existing IT infrastructure, including CAD/CAM, ERP, and MES systems.

ADVANTAGES

RAPID PART IDENTIFICATION

Instantly recognize parts from a batch in just 0.2 seconds with 90% accuracy.

AM-Vision revolutionizes post-processing workflows with unparalleled speed and accuracy in identifying 3D-printed parts. By leveraging advanced image recognition and AI algorithms, the system significantly reduces manual inspection efforts, ensuring precision and efficiency in your production line.

AI Driven

In-line Identification

LET US CHECK

YOUR PARTS

Feel free to send us your parts for testing.