MEDIA

Article type

- Article

- Brochure

- Case study

- E-book

- Event

- News

- Whitepaper

MEDIA TYPE

- Audio

- Image

- Video

PRODUCT

- AM-Feed

- AM-Vision

- AM-Sort

- AM-Quality

- AM-Bagging

AM-Flow, the Amsterdam and Brainport Eindhoven based Additive Manufacturing Automation company, today announced it has together with four other startups been awarded the FormNext Startup Challenge award. Formnext: “Five outstanding start-ups managed to win over this year’s jury with their innovations: Addiguru (USA), AM Flow (the Netherlands), Molyworks (USA), NematX (Switzerland), and TOffeeAM (UK). Molyworks…

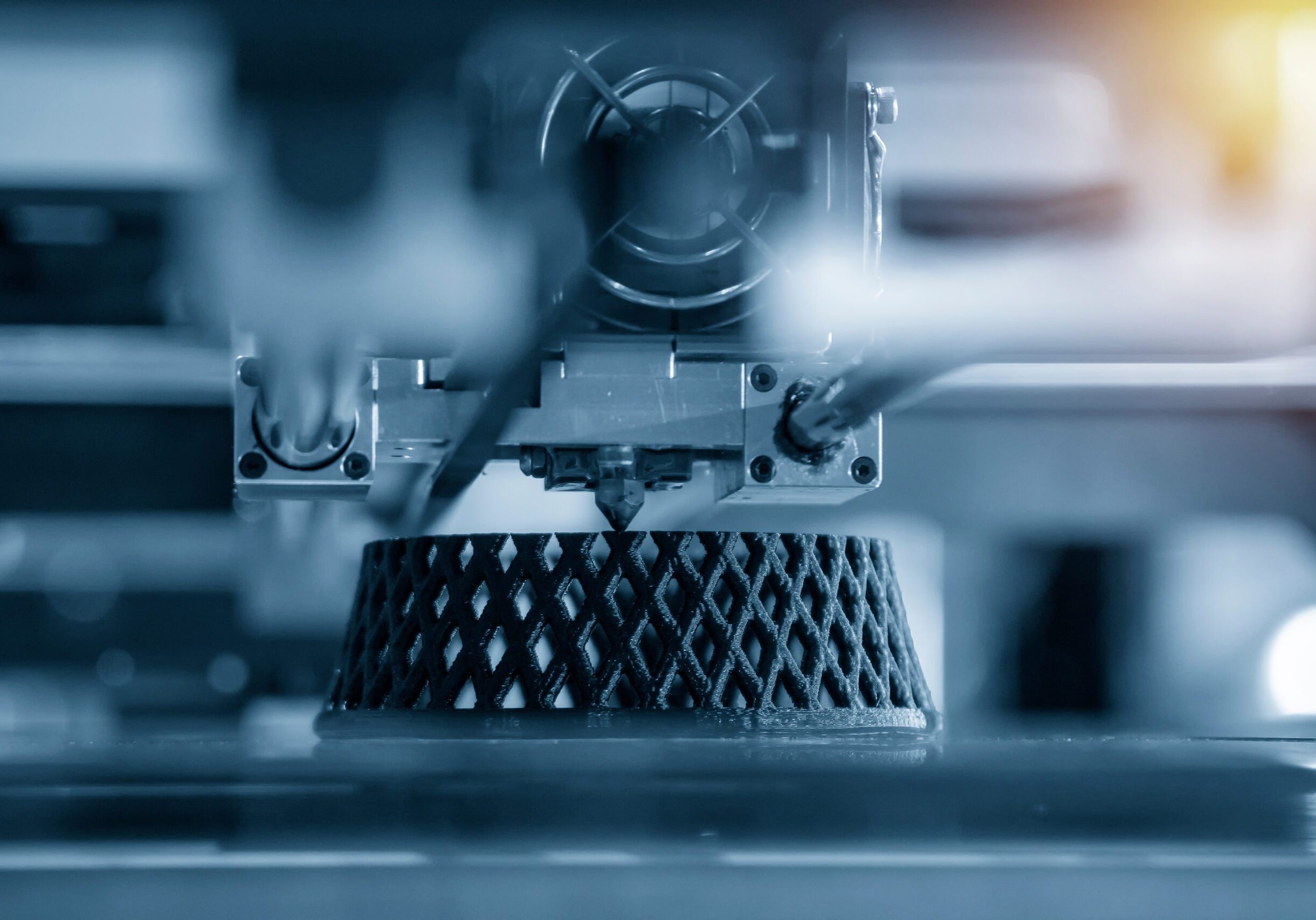

Automated AM production process3D printing, or Additive Manufacturing (AM), is now widely used to produce unique and serial parts for end use. The model design and the 3D printing process is digital, but after 3D printing, various manual process steps follow, such as identification and sorting. To produce 3D printed parts in series cost-effectively, AM-Flow…

3Faktur, experienced and highly professional additive manufacturing supplier located in Germany, is one of the pioneers to automate their AM workflow. 3Faktur sees a strong shift towards serial production, with rising expectations from prototyping towards ‘real’ industrial manufacturing. To address this and to scale production further, automating production and business processes is the way to…

At the production facility of Oceanz, the company has installed two integrated modules – AM-VISION and AM-SORT – which are now fully in the production. The AM-VISION provides fast automated identification of 3D printed parts. The accompanying AM-SORT, developed to sort parts quickly and with care with the patented flippers especially developed for the high…

Digitizing the AM-production process 3D-printing, or Additive Manufacturing (AM), is currently adopted and utilized across a broad spectrum of industries. The technology has developed beyond just a prototyping technology into a viable large-scale production technology as well. 3D CAD design and the 3D printing process are completely digitized, but after the 3D printing process itself,…

Established in 2018, AM-Flow is now a leader in automating additive manufacturing (the industrial face of 3D printing). “Our mission,” says Stefan Rink, CEO at AM-Flow “is providing the global AM Industry with cutting edge Industry 4.0 technology. Creating end-to-end digitized AM (3D Printing) production processes, and supporting to achieve the full potential of additive…

by Milan Lenters | Innovation Origins Almost everywhere, 3D-printed parts are still manually identified, sorted and finished. According to AM-Flow, this can be done faster and better via automation that uses sensors, data and AI. Manufacturers are using 3D printing increasingly as a manufacturing method. The Dutch market for industrial 3D printing will grow in…

Unshackled from the limitations associated with traditional production processes, AM has made the leap from prototype to end-part production, and continues to open up exciting opportunities around localised production, digital inventories and on-demand manufacturing. Yet, despite the technology’s many advantages, post-production remains a labour-intensive and costly process that presents a major barrier for companies looking…

In industry, 3D printing is becoming more and more viable and, thus, more important in production. As a result, we are now at the forefront of AM industrialization. This asks for specific solutions that fit 3D printing production processes. The solutions provided by AM-Flow address this acute need in the market. In addition, the fact…

AM-Flow, the Amsterdam and Brainport Eindhoven based industrial automation company for Additive Manufacturing factories, today announced it has completed a $4 million series A investment round. AM-Flow will use the investment to accelerate and support the 3D-printing industry by providing step-change automation, heading for the Lights Out Factory of the future. AM-Flow provides AI based…

- « Previous

- 1

- 2

- 3

- 4

- Next »