VISION TECHNOLOGY

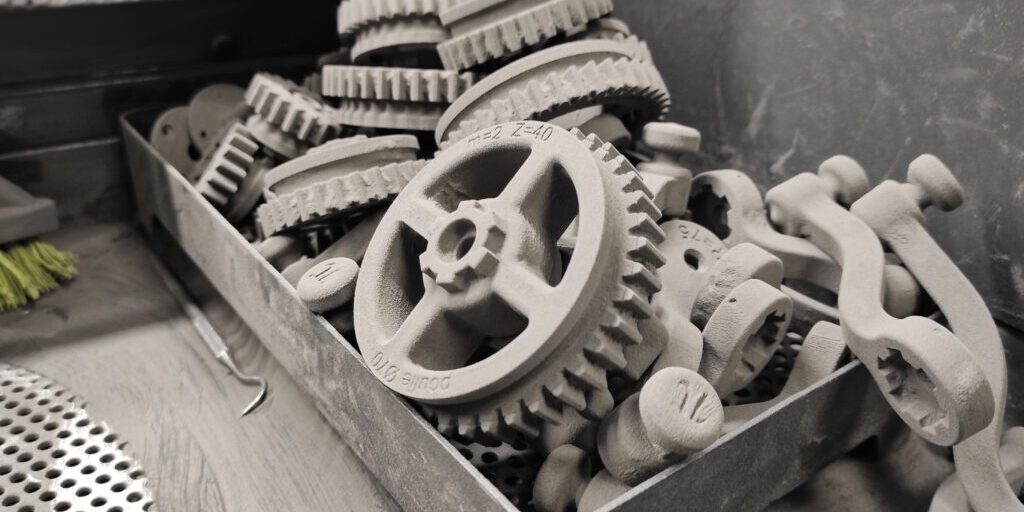

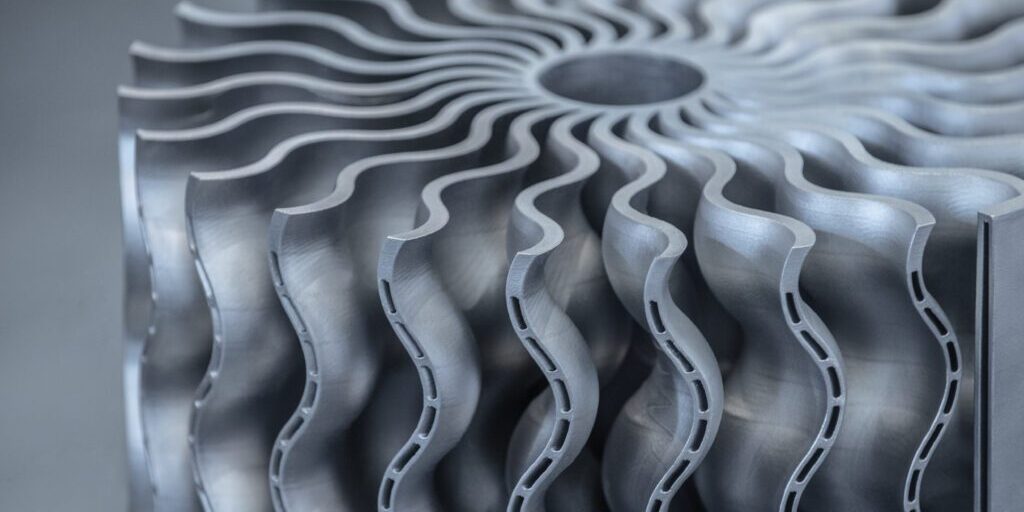

AM Flow utilizes cutting-edge AI technology to solve complex vision-related challenges in geometry, size, and color recognition. A printed part on a conveyor belt is tracked by LiDAR and photographed. These images are analyzed using AI-driven Deep Neural Networks, which predict the most probable digital design and assign the part if the confidence thresholds are met.

The recognition process involves pre-processing with a UNet-like Neural Network to identify the foreground map, and classification using three independent classifiers for shape, size, and color. The shape classifier, crucial for recognizing any geometry, leverages advanced techniques such as Self-Supervised Learning, Vision Transformer Encoding, and Transfer Learning. This sophisticated AI integration enables AM-Flow to excel in accurate and efficient shape recognition, even for previously unseen designs.

SOFTWARE

Our adaptive AI technology eliminates the need for machine changeovers, reprogramming, or extensive upfront training, allowing for the efficient processing of small series with infinite variations. With over six years of synthetic training and processing over two million production parts, our machine learning algorithms are not only fast and highly accurate, but also increasingly sophisticated. AM-Logic’s ultra-fast, geometry-based object recognition and pre-trained AI deliver precise results from the start. Combined with API integration into leading EMS or ERP systems and real-time business intelligence, AM-Logic provides a robust and intelligent solution to modern manufacturing challenges.

AM-Logic offers a revolutionary approach to factory automation, seamlessly integrating with your existing IT architecture and production modules. Our advanced software suite enhances intelligent process control and scalability, adapting effortlessly to your operational needs. Featuring APIs compatible with both traditional and 3D printing CAD/CAM, ERP, MES, and PLM systems, AM-Logic ensures that the digital backbone of your factory is always within reach, whether through static or mobile operator consoles.

COMPATIBILITY

Title

Content

Compatability

AM-Flow is particularly well-suited for advanced additive manufacturing techniques, offering significant benefits in automation, quality control, and efficiency enhancement. For traditional manufacturing methods, its integration can still provide improvements, particularly in post-processing and quality assurance, though the impact may be less pronounced compared to additive manufacturing environments.

PARTNERS

3D Printing & Finishing

Industrial Automation & Robotics

Vision & Metrology

MES SOFTWARE

Optimizing your post-processing operations is where we can add value and a competitive edge. AM-Flow excels in many

industries, providing technology that supports Additive Manufacturing no matter the field.

3D PRINTING SERVICE PROVIDERS

Leading service providers in the Additive Manufacturing industry, rely on our automatization post-processing technology to consistently improve their workflow processes and reduce the cost per part. Whether it's for one-off prototyping or high-volume production, our customers trust our solutions to address workflow challenges, reduce manual labor, cut costs and optimize lead times. By investing in our technology, companies can achieve scalable, efficient, and high-quality growth without compromising on customer experience and without the big investment in human resources. With AM-Flow, you can simplify complexity and gain control over your production processes.

MEDICAL

Additive manufacturing is transforming the landscape of medical innovation, offering personalized and effective solutions to improve patient care. This technology allows for the precise fabrication of patient-specific implants and surgical instruments, enhancing the efficiency and outcomes of medical procedures. Highly customized products require high-level quality control, that is usually performed manually by skilled operators and is a slow and costly process. Our solutions provide faster, better optimized post-production process workflow and quality control processes that result in shorter lead times with less human error and intervention.

AUTOMOTIVE

Additive manufacturing is advancing design flexibility and efficiency in the automotive industry, leading to more innovative and sustainable solutions. It accelerates the creation and testing of complex parts, produces lightweight, high-strength components for better performance and fuel efficiency, and supports on-demand production. Producing parts at scale, however, still has the potential to create bottlenecks in the post-processing stages. Therefore, AM-Flow’s automated identification, sorting, and quality control solutions can be the perfect way to streamline operations and ensure reproducible and traceable processes.

AEROSPACE

Additive manufacturing is revolutionizing aerospace by producing lightweight, high-strength components with complex geometries. This technology enhances design flexibility, leading to more efficient parts that reduce aircraft weight and improve fuel efficiency. It also supports rapid prototyping and on-demand production of spare parts. The intricately designed parts are challenging for traditional production, sorting and quality control. AM-Flow is addressing those issues by providing partially or fully automated solutions that are able to handle an infinite variety of geometries, materials and assembly combinations.