MEDIA

Article type

- Article

- Brochure

- Case study

- E-book

- Event

- News

- Whitepaper

MEDIA TYPE

- Audio

- Image

- Video

PRODUCT

- AM-Feed

- AM-Vision

- AM-Sort

- AM-Quality

- AM-Bagging

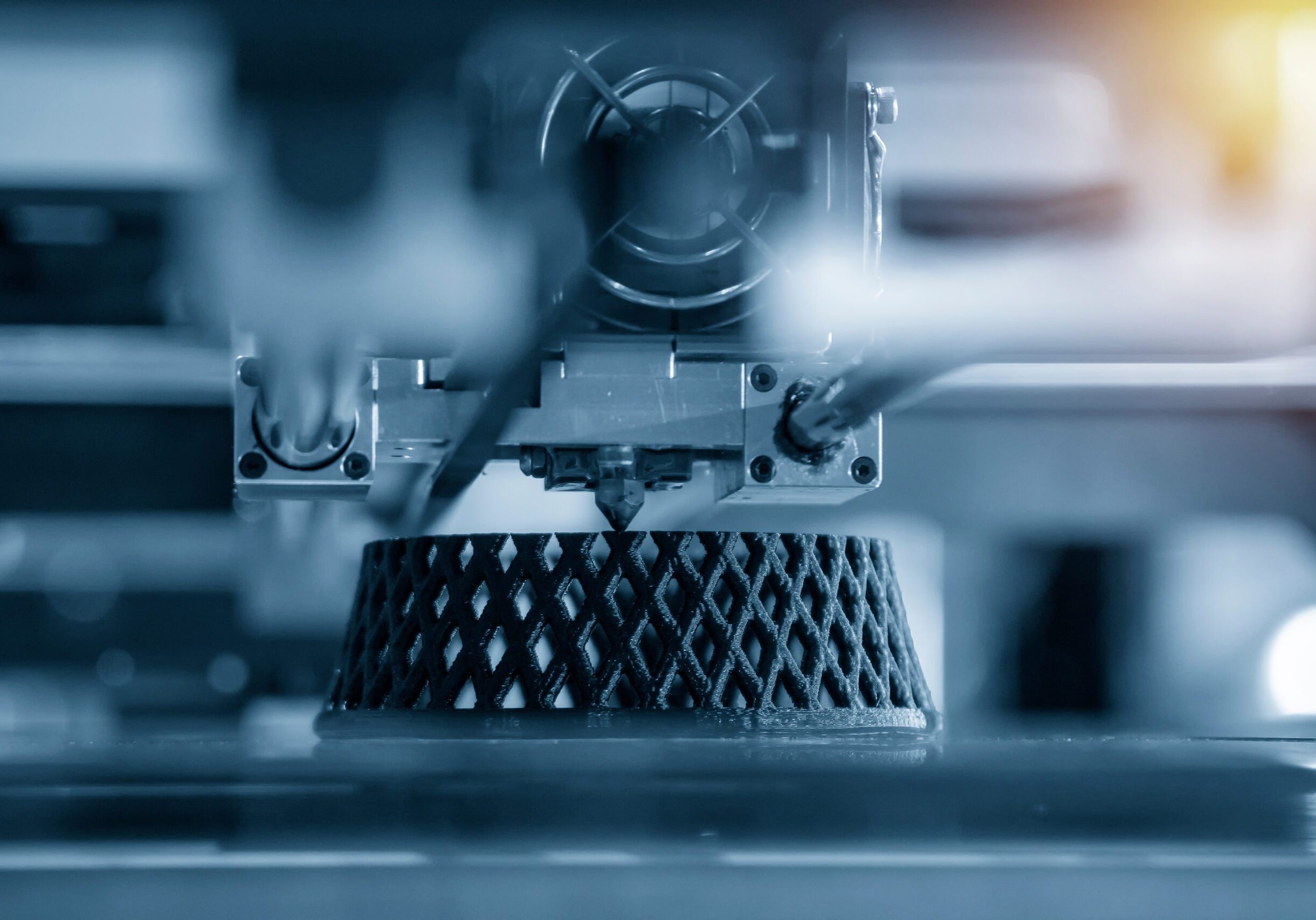

The counterintuitive truth about scaling additive manufacturing operations When most AM service providers hit capacity constraints, their first instinct is to buy more printers. More machines equal more output, right? After working with dozens of 3D printing facilities worldwide, we’ve learned this approach often misses the biggest opportunity for sustainable growth. The real leverage isn’t…

This article explores AM-Quality, the world’s first in-line quality control solution, designed to provide the speed, precision, and scalability at the heart of AM-Flow’s vision. Manufacturers constantly face the challenge of maintaining consistent quality in high-volume production. Traditional quality control methods are becoming outdated due to inefficiencies, reliance on manual labor, subjective assessments, tooling obstructions,…

Automated identification, quality control, and sorting to enhance efficiency, reliability, and process control Eindhoven, [25/03/2025] – Weerg, a pioneer in additive manufacturing, is taking a significant step forward in automation with the implementation of AM-Flow’s fully integrated production line. By leveraging advanced identification, quality control, and sorting technologies, Weerg aims to streamline its post-processing workflow,…

Automated solutions in post-processing address the challenges of 3D printing workflows, allowing for more precise sorting, efficient handling of diverse parts, and rapid iteration without manual bottlenecks.

From single part to infinity and back: learn how AM-Flow helps additive manufacturing companies on their voyage of automation, from the first steps to massively scaled digital production.

AM-Flow’s automated solution for part identification and sorting drives down the cost-per-part of 3D printing, enabling scalability like never before.

The road to a fully automated and digitalized additive manufacturing factory of the future.

Image: Siemens AG – Additive Manufacturing In the past three decades, additive manufacturing (AM), a.k.a. 3D printing has seen a flight in investment in printing technologies, driven by companies starting to carve out their position in the AM market. These investments were necessary to get the printing technology to a quality level that would be…

The AM-VISION provides fast automated identification of 3D printed parts. The accompanying AM-SORT, developed to sort parts quickly and with care, with the patented flippers especially developed for the high variety of 3D printed parts, ensures that identified models are guided to the correct next process step. The AM-LOGIC software suite guarantees seamless integration of…

Ltr: Bill Isermann, Suzanne Brasure, Steve Grundahl, Nick Janssen (AM-Flow), Trent Appleby The company is one of the first clients of AM-Flow using the AM-Flow’s vision technology. This moment marks the step to the brand new, next generation VISION and SORT. With these production modules, Midwest Prototyping is able to fully automated recognize, sort and…