“Just like other 3D-printservice providers, several post processing steps are done manually at Oceanz. The increase in costs and lead times due to these manual steps has made us realize the necessity to develop and apply new technologies, such as automatic identification, Artificial Intelligence (AI) and machine learning. We have opened up our production facility as a ‘living lab’ to develop these technologies. This partnership is unique and necessary to optimize post-production processes in terms of quality and speed”, according to Erik van der Garde, CEO Oceanz 3D-printing.

Computer Vision and AI are the core technologies for quality assessment and sorting of AM-products.

The concept production line as AM-Flow presented at this RapidPro will be further developed together with Oceanz and tested in a real life production environment.

Larger companies want to scale with 3D Printing

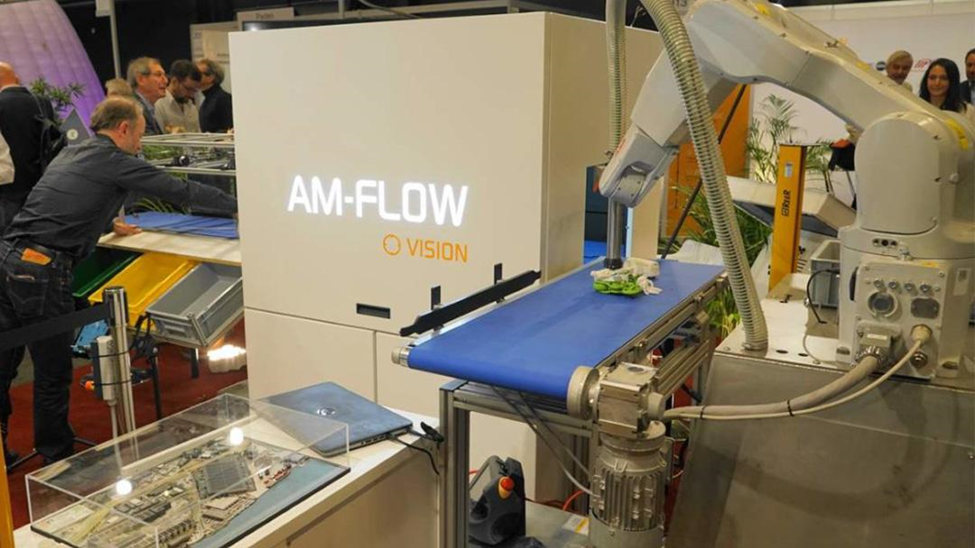

AM-Flow show cased a couple of weeks ago at the RapidPro their next step of their vision of automating the whole 3D print process including post processing. Carlos Zwikker, Commercial Director at AM-Flow, says it’s the right time to develop this type solutions.

“Some larger AM entities already have a high volume/high mix production. EOS is working on their Fusion technology. Everybody is growing towards larger volumes. The bigger players now want to scale up with 3D Printing.” This can only happen if 3D printed parts can be identified before the next post processing steps.

Also automate visual quality assessment

In Veldhoven, the Dutch tart-up presented a concept production line, in which a robot identifies 3D printed parts and then a second unit has them sorted. This process uses the AI-of van AM-Flow combined with computer vision. While parts are being printed, their system makes 360° renderings. When a 3D printed part passes through the robot, computer vision images are taken and overlaid over the renderings. An algorithm then calculates the level of recognition in 0,2 seconds. This is how 3D printed parts can be identified and sorted.

“Together with Oceanz will further develop this concept production line and also include quality assessment”, says Carlos Zwikker. This technology with additional metrology technology will be the basis of visual quality assessment. They are even working on a system that can flip objects to be able to assess quality from all angles.

AM-Flow uses Artificial Intelligence to identify and sort 3D printed products

AM becoming a serious technology for high volume production

AM-Flow connects their system to the ERP-system of a 3D printing entity. At RapidPro, AM-Flow Carlos presented the first version of a management dashboard. In the meantime, additional functionalities are being looked into. The partnership with Oceanz, where all concepts will be tested real life, needs to lead to an industrial solution for 3D printing for it to be considered a serious production technology.

“Now is the time that Additive Manufacturing becomes a serious alternative for traditional mass production methods. To achieve this, we have to create a fully digital workflow and minimize manual processes. With our AM-FLOW technology, we are able to offer this end-to-end digital industrialization.”

Stefan Rink, CEO of AM-Flow